Dongguan Hie Hardware Co., Ltd is a metal products enterprise with a profound history of twenty

years. We are an integrated entity that combines research and

development, manufacturing, sales, and service. We are not only an

OEM processing manufacturer for many domestic and foreign mold

accessories counterparts but also a pioneer in the field of

minimally invasive surgical instruments.

In the design and manufacture of minimally invasive surgical

instrument structural components and fine metal combination pipe

fittings, we focus on the design and manufacture of minimally

invasive surgical structure space components, covering surgical

components such as endoscopic structures, ablation structures,

puncture analysis, sampling biopsy analysis, endoscopic

intervention, suture cutting, heart stents, and vascular stents.

Our technical team with twenty years of manufacturing experience

has broken through various technical barriers in minimally invasive

structure manufacturing, effectively addressing the high complexity

of the process of minimally invasive instrument structural

components. With advanced manufacturing processes such as

multi-pole expansion and contraction, non-standard surface marking,

arbitrary latitude bending, step forming, multiple side holes,

multi-axis welding, six-axis component forming, pipe body expansion

and contraction, micro-tube cutting, multi-level surface

perforation, surface partial insulation, surface partial roughness,

clean slender inner tubes, and non-sticking liquid in

liquid-conducting tubes, we can meet the design needs of various

high-difficulty special-shaped parts for customers and have

received unanimous recognition and long-term cooperation from

domestic and foreign customers.

In the field of mold accessories manufacturing, our technical

backbones have decades of processing experience in mold parts from

Japan and Taiwan. The company regularly conducts various skill

trainings and grade evaluations to lay a solid foundation for

continuous development in the mold parts manufacturing industry and

gradually move towards industry standardization and modernization.

We always strictly follow the technical standards of manufacturers

such as "MISUMI", "Punch", "DME", and "HASCO" for production and

inspection. We can also design and provide various standard and

non-standard mold accessories according to different customer

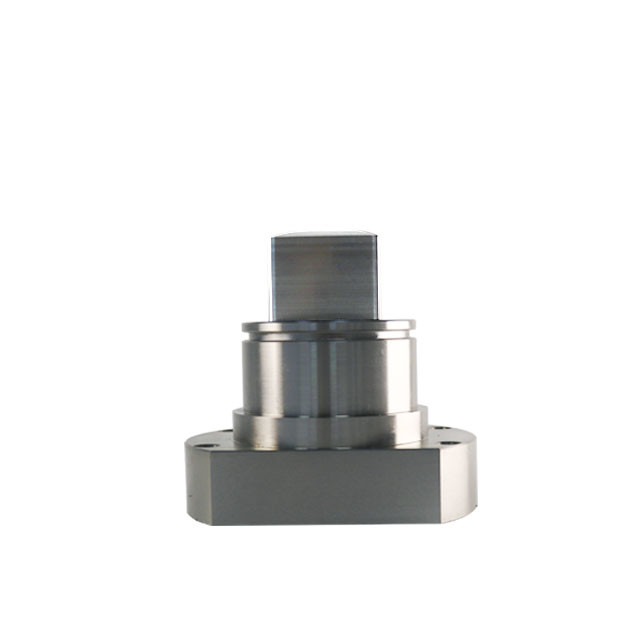

requirements. We specialize in manufacturing precision

photoelectric tooth shafts, screw thread electrodes, pen mold

cores, cosmetic parts, precision inserts, cores, bushings, and

SKH51/SKD61 series cartridge ejector pin mold accessories, etc. Our

products are widely used in fields such as photoelectric, digital

electronics, medical packaging instruments, pen making, cosmetic

packaging, electrical appliances, automobiles, and mechanical motor

shaft manufacturing. In particular, we have significant advantages

in non-standard mold accessories processing, various wear-resistant

block processing, guide pillar and bushing processing, non-standard

insert processing, precision plastic mold accessories processing,

etc., providing customers with a full range of solutions for

precision mold accessories processing.

The company holds multiple independent product structure

manufacturing patents and has passed ISO9001:2015 and ISO13485

quality system certifications. With excellent quality, exquisite

craftsmanship, innovative design, and high-quality service, we are

committed to creating greater value for customers.