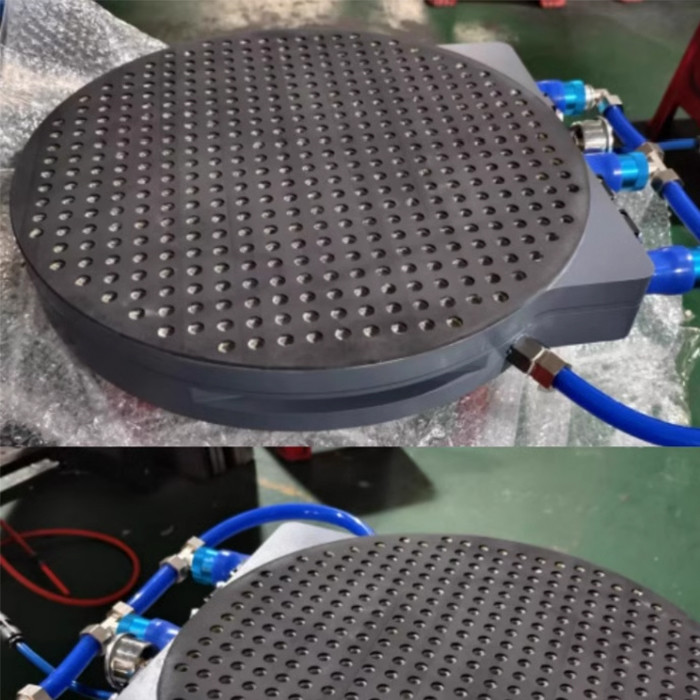

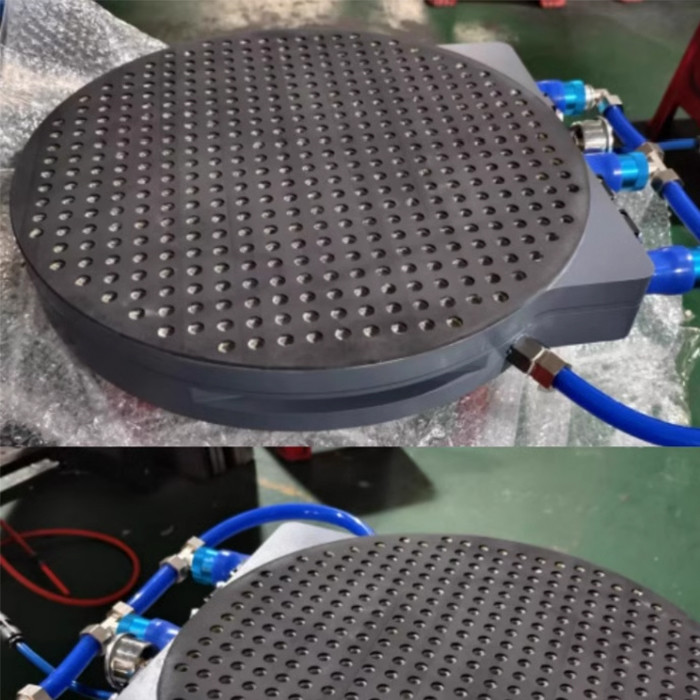

Replaceable Chuck Plates: A Key Advantage

Adaptability to Different Workpiece Sizes and Shapes

One of the primary benefits of having replaceable chuck plates is

the ability to handle a wide range of workpiece sizes and shapes.

For small, intricate parts commonly found in the electronics or

jewelry industries, a chuck plate with a finely - detailed surface

and smaller vacuum - channel patterns can be installed. This

ensures a secure hold on delicate components without causing any

damage. On the other hand, for larger and bulkier workpieces, such

as those in the automotive or aerospace sectors, a chuck plate with

a larger surface area and more robust vacuum channels can be used.

The replaceable nature of the plates allows for seamless

transitions between different production runs, eliminating the need

to invest in multiple fixed - type chucks.

Material - Specific Compatibility

Different materials require different handling during machining.

For example, when working with soft materials like wood or certain

plastics, a chuck plate with a non - marring surface is essential

to prevent scratches or dents. In contrast, when machining hard

metals such as steel or titanium, a chuck plate made of a durable

and heat - resistant material is needed to withstand the high

forces and temperatures generated during the machining process. The

Custom Modular Vacuum Chuck Kit allows for the use of chuck plates

specifically tailored to the material being processed, ensuring

optimal performance and workpiece quality.

Applications in CNC Machining Centers

Precision Machining Operations

CNC machining centers are known for their ability to perform highly

precise machining tasks. The modular vacuum chuck kit plays a

crucial role in maintaining this precision. By providing a stable

and consistent holding force, it minimizes vibrations and

displacements during machining. This is especially important for

operations such as milling, drilling, and turning, where even the

slightest movement of the workpiece can result in a defective part.

For instance, in the production of medical implants, where

precision is of utmost importance, the vacuum chuck kit ensures

that each part is machined to the exact specifications, meeting the

strict quality standards of the medical industry.

High - Volume Production

In high - volume production environments, time is money. The quick

- change feature of the replaceable chuck plates significantly

reduces setup times. Instead of spending hours re - adjusting or

replacing an entire chuck system, operators can simply swap out the

chuck plate in a matter of minutes. This allows for rapid

transitions between different product models or batches, increasing

the overall productivity of the CNC machining center. For example,

in a manufacturing facility that produces a variety of consumer

electronics components, the modular vacuum chuck kit enables the

efficient production of large quantities of different parts,

meeting tight production schedules.

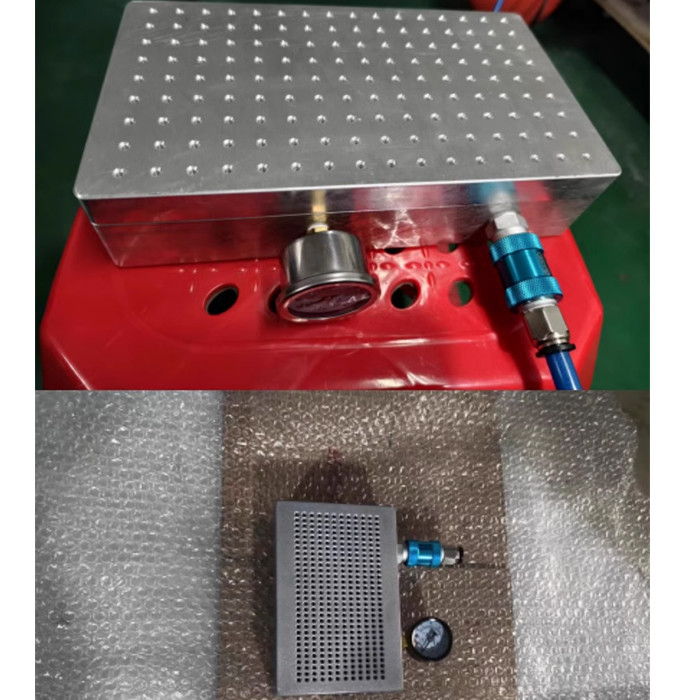

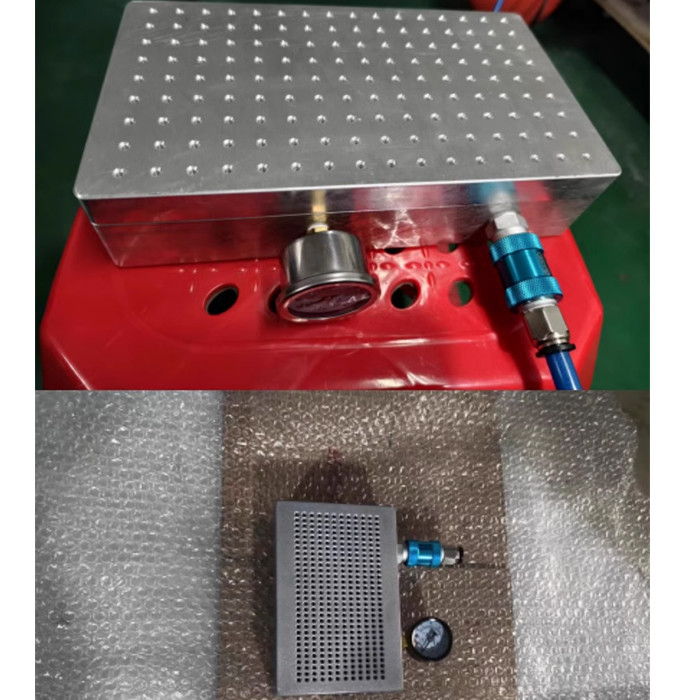

Customization Options

The Custom Modular Vacuum Chuck Kit offers extensive customization

possibilities. The base unit can be customized in terms of its

vacuum - generating capacity to suit the specific requirements of

the machining center. Additionally, the chuck plates can be custom

- designed with unique vacuum - channel configurations, surface

textures, and mounting options. This level of customization ensures

that the kit can be tailored to the exact needs of each customer,

whether they are a small - scale job shop or a large - scale

manufacturing enterprise.

In conclusion, the Custom Modular Vacuum Chuck Kit with Replaceable

Chuck Plates is a game - changer for CNC machining centers. Its

modular design, replaceable chuck plates, wide range of

applications, and customization options make it an invaluable tool

for achieving precision, versatility, and efficiency in modern

machining operations. If you are looking to enhance the performance

of your CNC machining center, this custom modular vacuum chuck kit

is the ideal solution.