2. Design and Working Principle of Large Magnetic Vacuum Chucks

Construction of Magnetic Vacuum Chucks

Large magnetic vacuum chucks are typically constructed with a base

made of high - strength, non - magnetic materials such as stainless

steel or specialized alloys. This base provides a stable foundation

for the chuck's operation and helps in isolating the magnetic and

vacuum systems from external interference.

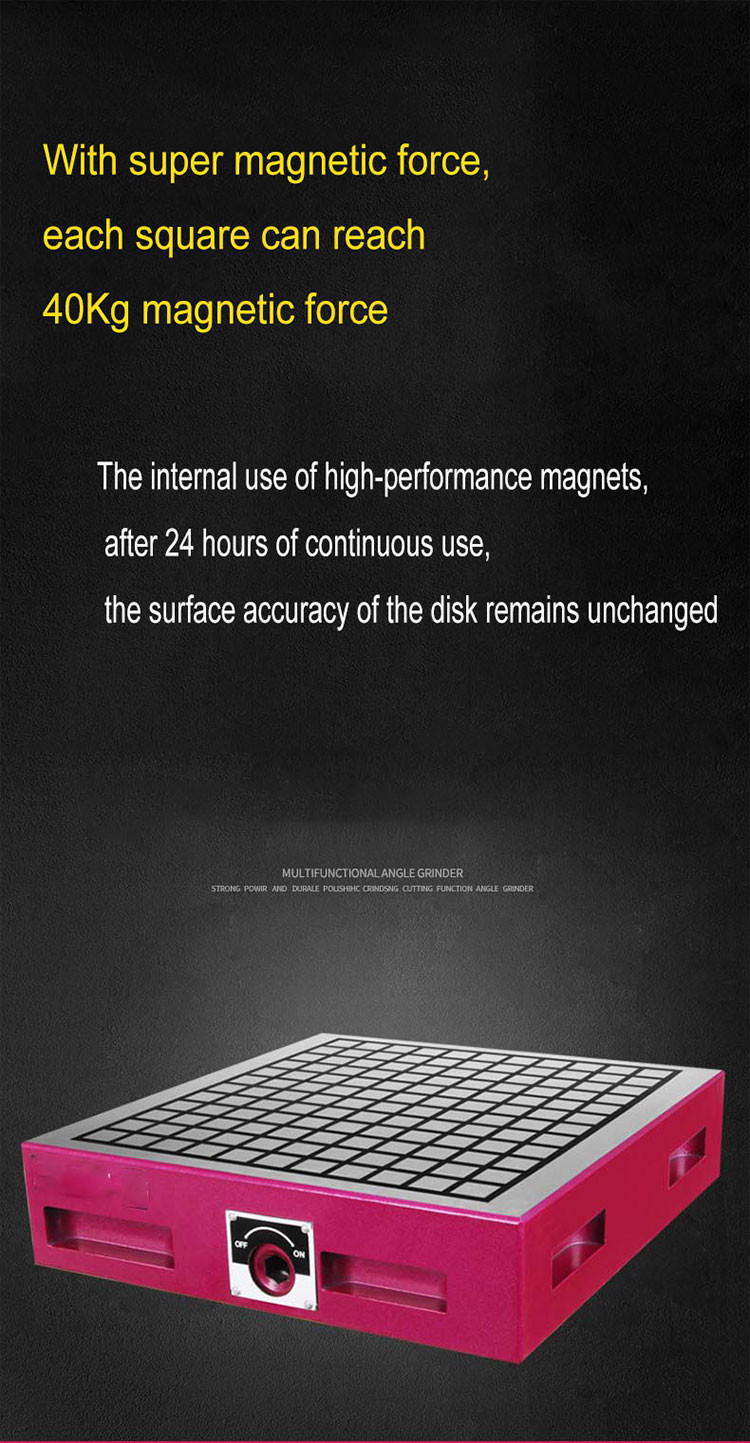

Embedded within the base are powerful permanent magnets, often made

of rare - earth materials like neodymium. These magnets are

arranged in a strategic pattern to generate a strong and uniform

magnetic field across the chuck's surface. The magnetic field is

designed to attract ferromagnetic elements present in the high -

tensile cast aluminum alloy, providing an initial holding force.

The surface of the chuck is designed with a network of channels and

ports that are connected to a vacuum source. These channels are

carefully engineered to ensure even distribution of the vacuum

force across the workpiece. The surface itself is precision -

machined to a high degree of flatness, which is crucial for both

magnetic and vacuum - based workholding. In some cases, the surface

may be further treated with a non - abrasive coating to protect the

workpiece and enhance the magnetic and vacuum adhesion.

Working Principle

When a precision - ground high - tensile cast aluminum workpiece is

placed on the large magnetic vacuum chuck, the permanent magnets

immediately generate a magnetic force that attracts the workpiece.

The ferromagnetic components in the aluminum alloy are drawn

towards the magnetic field, providing an initial hold. This

magnetic force helps in positioning the workpiece accurately on the

chuck and also maintains close contact between the workpiece and

the chuck surface, which is essential for effective vacuum

operation.

Once the workpiece is in place, the vacuum system is activated. The

vacuum source draws air out through the channels on the chuck

surface, creating a pressure differential between the top and

bottom of the workpiece. This pressure differential, combined with

the magnetic force, results in a strong and secure hold on the

workpiece. The magnetic force acts as a complementary force to the

vacuum force, ensuring that the workpiece remains firmly in place

even during high - speed machining operations or when subjected to

significant cutting forces.

3. Advantages of Large Magnetic Vacuum Chucks for High - Tensile

Cast Aluminum

Precise Workpiece Holding

In precision grinding of high - tensile cast aluminum, accurate

workpiece holding is of utmost importance. The large magnetic

vacuum chucks offer a stable and secure hold, minimizing any

movement or vibration of the workpiece during the grinding process.

The uniform distribution of magnetic and vacuum forces across the

workpiece surface ensures that the grinding wheel makes even

contact with the workpiece, resulting in a smooth and accurate

surface finish.

For example, in the production of aerospace components made of high

- tensile cast aluminum, the precise holding provided by the

magnetic vacuum chuck allows for the achievement of tight

tolerances, ensuring the proper fit and functionality of the

parts.

Protection of Workpiece Surface

High - tensile cast aluminum has a relatively soft surface compared

to some other metals, and it is easily damaged by traditional

clamping methods. The large magnetic vacuum chucks provide a gentle

yet strong hold, reducing the risk of surface scratches, dents, or

deformation. The magnetic and vacuum forces are distributed evenly

across the workpiece, eliminating the need for concentrated

clamping points that could cause damage.

This is particularly important in applications where the surface

finish of the workpiece is critical, such as in the manufacturing

of optical components or high - precision mechanical parts. The

protection of the workpiece surface also reduces the need for

additional post - processing steps, saving time and costs.

Adaptability to Different Workpiece Sizes and Shapes

Large magnetic vacuum chucks are highly adaptable to different

workpiece sizes and shapes. Whether it's a small, intricate

component or a large, flat panel made of high - tensile cast

aluminum, the chucks can provide a secure hold. The magnetic force

can conform to the shape of the workpiece, and the vacuum system

can still create a sufficient hold as long as there is enough

surface area in contact with the chuck.

For example, in the automotive industry, where high - tensile cast

aluminum is used for engine blocks and body panels, the magnetic

vacuum chucks can hold components of various sizes and geometries

during machining. This adaptability makes the chucks suitable for a

wide range of applications in different industries.

4. Applications in Different Industries

Aerospace Industry

In the aerospace industry, high - tensile cast aluminum is widely

used due to its lightweight and high - strength properties. Large

magnetic vacuum chucks are used for machining critical components

such as aircraft wings, fuselage sections, and engine parts. The

precise workholding provided by the chucks ensures that these

components meet the strict quality and safety standards of the

aerospace industry.

For example, when grinding the surface of an aircraft wing made of

high - tensile cast aluminum, the magnetic vacuum chuck holds the

large and complex - shaped workpiece securely, allowing for the

removal of material with high precision. This results in a smooth

surface finish that is essential for aerodynamic performance.

Automotive Industry

The automotive industry also benefits from the use of large

magnetic vacuum chucks for machining high - tensile cast aluminum

components. These chucks are used for manufacturing engine blocks,

cylinder heads, and suspension parts. The ability to hold the

workpiece firmly during machining ensures accurate machining of the

components, which is crucial for the performance and reliability of

the vehicle.

For instance, when machining the cylinder bores in an engine block

made of high - tensile cast aluminum, the magnetic vacuum chuck

provides a stable hold, allowing for the creation of precise and

smooth - walled bores that are essential for the proper functioning

of the engine.

Electronics Industry

In the electronics industry, high - tensile cast aluminum is used

for heat sinks and enclosures for electronic devices. Large

magnetic vacuum chucks are used to hold these components during

precision grinding and machining operations. The protection of the

workpiece surface provided by the chucks is especially important in

the electronics industry, where any surface damage could affect the

performance of the electronic device.

For example, when grinding the surface of a high - tensile cast

aluminum heat sink to improve its heat dissipation efficiency, the

magnetic vacuum chuck holds the delicate component securely,

ensuring that the grinding process is carried out without causing

any damage to the surface.

5. Customization and Maintenance

Customization Options

Large magnetic vacuum chucks can be customized to meet the specific

needs of different industries and applications. The size, shape,

and magnetic field configuration of the chuck can be tailored to

fit the dimensions and requirements of the workpiece. The vacuum

system can also be adjusted to provide the appropriate level of

vacuum pressure for different materials and machining processes.

For example, in a manufacturing process where a large number of

small, irregularly shaped high - tensile cast aluminum parts need

to be machined, the magnetic vacuum chuck can be designed with a

high - density pattern of magnetic poles and vacuum ports to ensure

a secure hold on each part.

Maintenance Requirements

Maintenance of large magnetic vacuum chucks is relatively

straightforward. Regular inspection of the chuck's surface for any

signs of wear, damage, or contamination is important. The magnetic

components should be checked for any signs of demagnetization, and

the vacuum system should be inspected for leaks.

The vacuum channels and ports should be cleaned periodically to

ensure proper air flow. The seals and gaskets in the vacuum system

should be checked and replaced if necessary. The magnetic strength

of the chuck can be periodically tested and adjusted if required.

By following these maintenance procedures, the magnetic vacuum

chuck can maintain its performance and reliability over an extended

period.

6. Conclusion

Large magnetic vacuum chucks are an essential workholding solution

for precision - ground high - tensile cast aluminum. Their unique

combination of magnetic and vacuum - based workholding, along with

their adaptability and ability to protect the workpiece surface,

makes them suitable for a wide range of applications in different

industries. Whether it's in the aerospace, automotive, or

electronics industry, these chucks play a crucial role in ensuring

the accuracy and quality of machined high - tensile cast aluminum

components. If you are involved in machining high - tensile cast

aluminum and are looking for a reliable and efficient workholding

solution, consider investing in large magnetic vacuum chucks. Reach

out to our team of experts to explore how these chucks can be

customized to meet your specific needs and take your machining

capabilities to the next level.